Solvent

Extraction Method of Edible Oil Using Hexane

Introduction

The solvent extraction method is

one of the most widely used industrial processes for producing edible oils from

oilseeds such as soybean, sunflower, groundnut, rice bran,

cottonseed, mustard, and corn germ.

This method is especially preferred when the oil content of seeds is low or

when maximum oil recovery is required.

Among various solvents, hexane is

the most commonly used solvent in the edible oil industry due to its high oil

solubility, low boiling point, easy recovery, and cost-effectiveness.

Why Hexane Is Used as a Solvent

Hexane is a petroleum-derived organic solvent that has

ideal properties for oil extraction:

· Excellent

solubility for vegetable oils

· Low

boiling point (~65–70°C), making recovery easy

· Chemically

stable and non-reactive with oil

· High

extraction efficiency (up to 98–99%)

· Economical

and reusable after recovery

Because of these advantages, food-grade

hexane is widely accepted in edible oil processing plants

worldwide.

Raw Materials Used

Solvent extraction is mainly used for:

· Soybean

· Rice

bran

· Sunflower

seed

· Cottonseed

· Mustard

seed

· Groundnut

cake (after expelling)

· Corn

germ

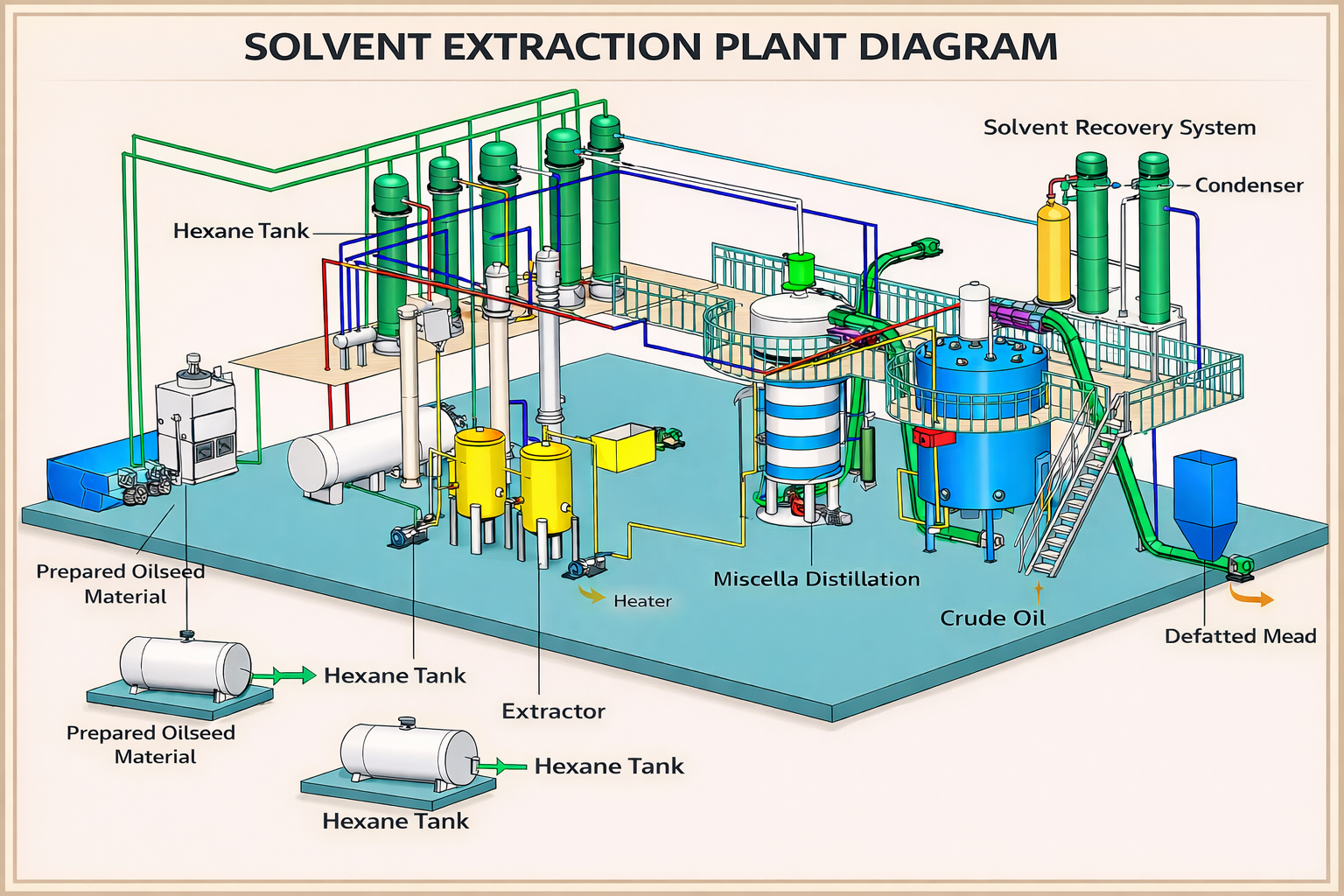

Step-by-Step Solvent Extraction

Process

1. Seed Preparation

Oilseeds are first cleaned to remove dust, stones, metal

particles, and foreign matter.

Then they undergo:

· Dehulling (removal

of husk, if required)

· Crushing

or flaking to increase surface area

· Conditioning by

heating to optimize oil release

Proper preparation ensures efficient solvent penetration.

2. Extraction with Hexane

Prepared flakes or cake are fed into the extractor.

· Hexane

is sprayed or percolated through the material

· Oil

dissolves into hexane, forming a mixture called miscella (oil

+ hexane)

· The

remaining solid material becomes defatted meal

At this stage:

· Oil

recovery can reach 98–99%

· Minimal

oil remains in the meal

3. Miscella Distillation (Oil

Recovery)

The miscella is heated in distillation

units:

· Hexane

evaporates at low temperature

· Oil

is separated and collected

· Evaporated

hexane is condensed and reused

The recovered oil at this stage is called crude oil.

4. Desolventizing of Meal

The defatted meal still contains traces of hexane.

· Meal

is sent to a Desolventizer-Toaster (DT)

· Steam

and heat remove remaining hexane

· Hexane

vapors are recovered and reused

The final meal is:

· Safe

for animal feed or food applications

· High

in protein (especially soybean meal)

5. Solvent Recovery System

To ensure safety and economy:

· All

hexane vapors are condensed

· Recovered

hexane is recycled back into the system

· Losses

are kept extremely low

Modern plants achieve over 99.5% solvent recovery.

Post-Extraction Refining of Oil

The crude oil obtained by solvent extraction is not directly

edible.

It undergoes refining steps such as:

1.

Degumming –

Removal of phospholipids

2.

Neutralization –

Removal of free fatty acids

3.

Bleaching –

Removal of color pigments

4.

Deodorization –

Removal of odor and taste

After refining, the oil becomes Refined,

Bleached, and Deodorized (RBD) edible oil, suitable for human

consumption.

Advantages of Solvent Extraction

Method

· Very

high oil recovery (maximum yield)

· Economical

for large-scale production

· Suitable

for low-oil-content seeds

· Produces

high-protein defatted meal

· Continuous

and automated process

Safety and Environmental

Considerations

Hexane is flammable, so modern plants include:

· Explosion-proof

equipment

· Vapor-tight

systems

· Fire

detection and suppression

· Strict

monitoring of solvent losses

Food-grade hexane residues in oil are removed completely

during refining, making the final oil safe for consumption as

per international standards.

Conclusion

The solvent extraction method using hexane is

a highly efficient, proven, and globally accepted technology for edible oil

production.

It ensures maximum oil recovery, consistent quality, and economic viability,

especially for large-scale edible oil plants.

With advanced solvent recovery and refining systems, this

method plays a crucial role in meeting the growing global demand for

high-quality edible oils.